November 2, 2023•

In The News•

Bill Hall

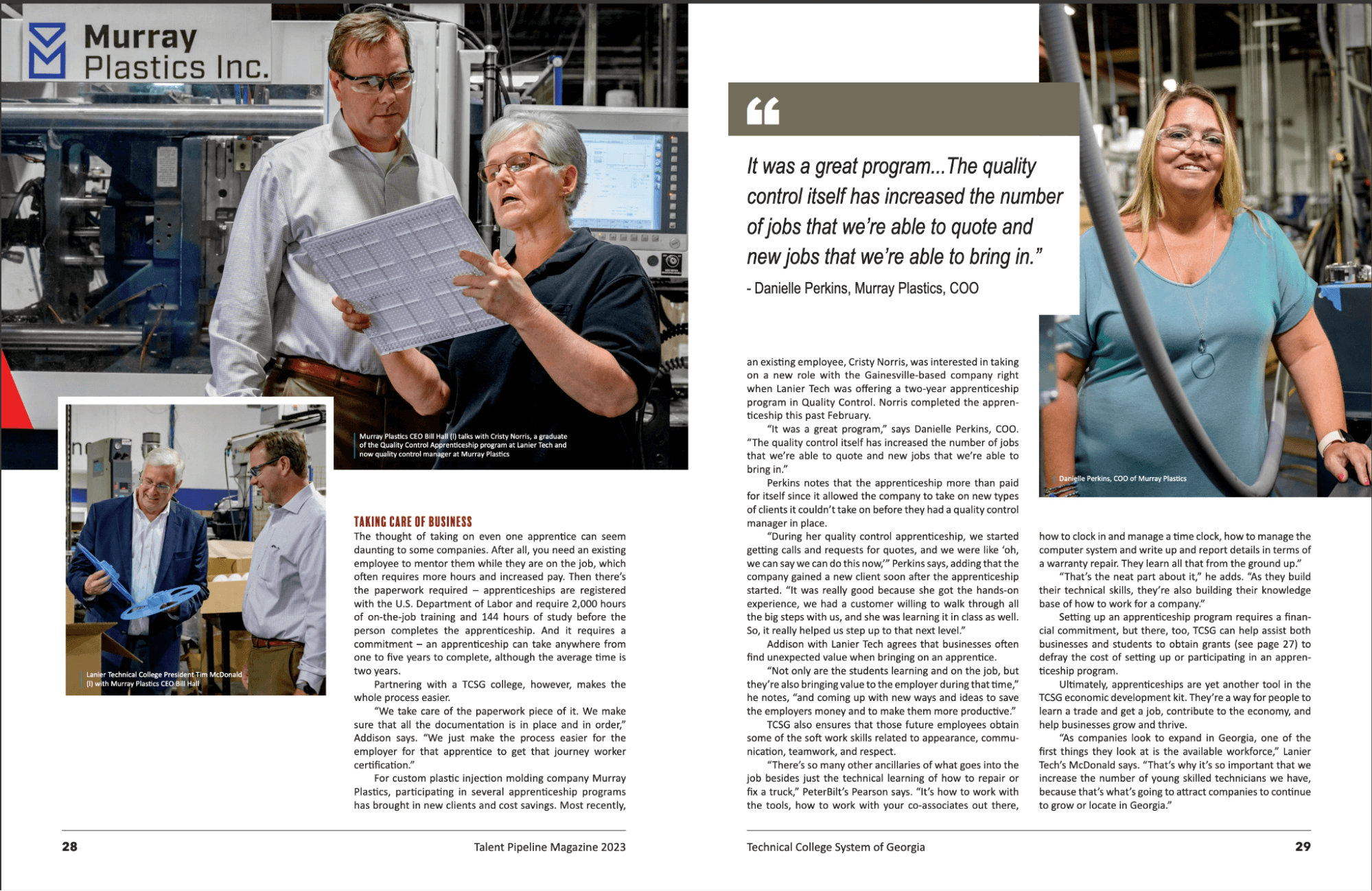

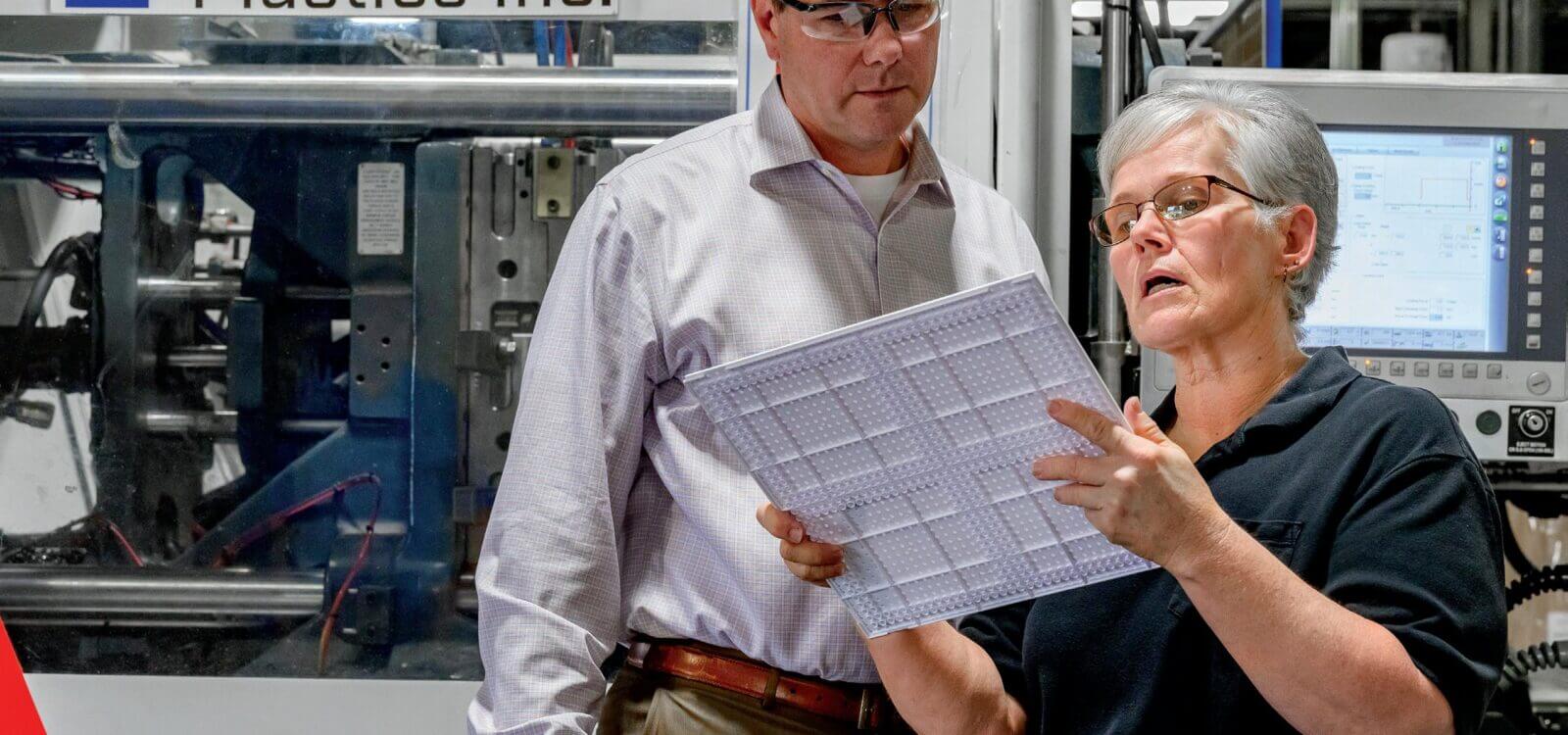

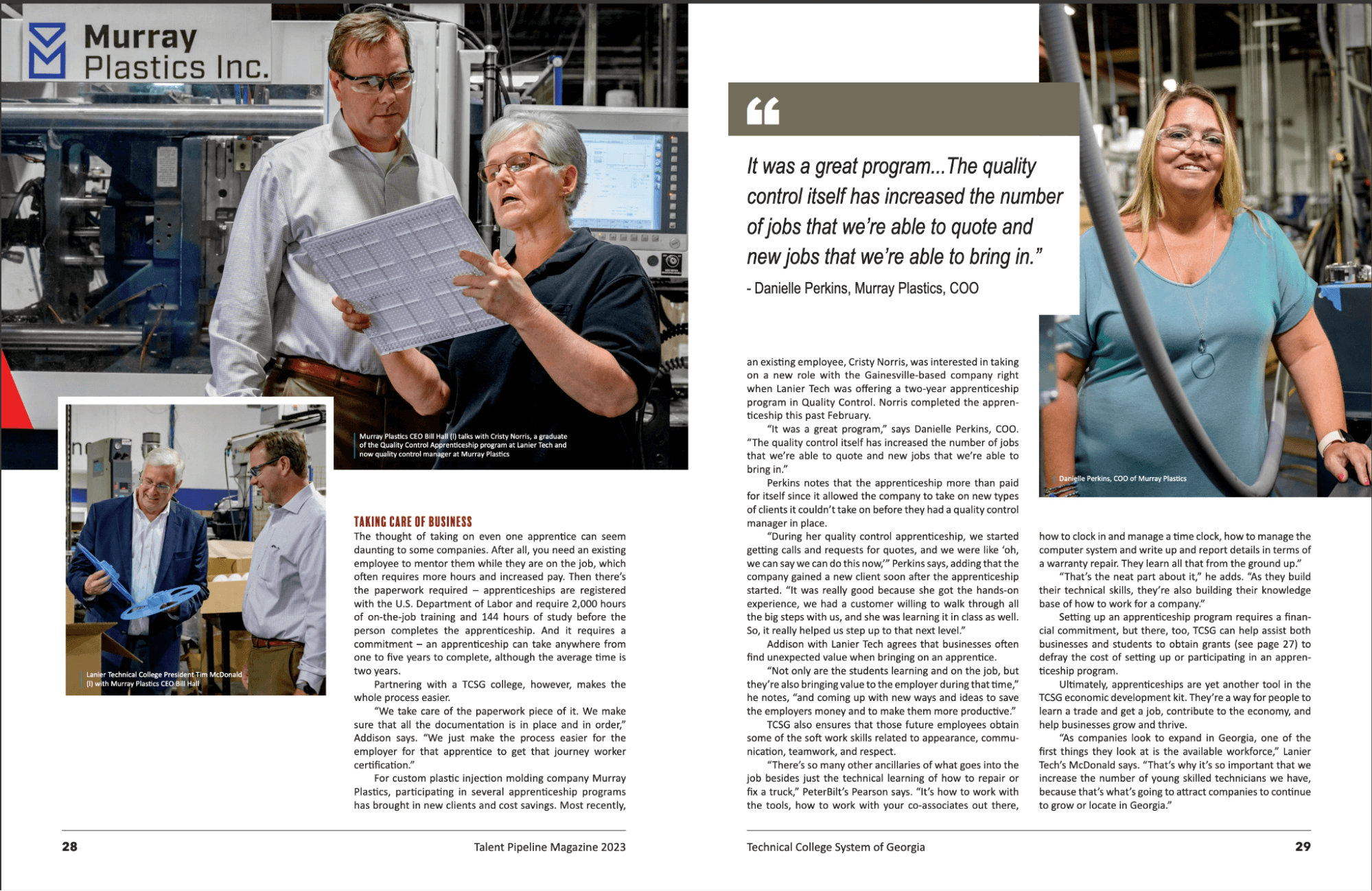

Murray Plastics, a distinguished player in the custom plastic injection molding industry, is proudly featured in Talent Pipeline magazine for its pioneering approach to workforce development through apprenticeship programs. This spotlight article underscores how Murray Plastics strategically collaborated with Lanier Tech, a crucial component of the Technical College System of Georgia (TCSG), to foster talent, optimize their operations, and captivate new clients.

In the world of plastic injection molding, staying ahead of the curve is paramount. With advancements in technology and a growing demand for precision, the need for skilled professionals in the field is more critical than ever. To tackle this challenge, plastic injection mold businesses can form partnerships with technical colleges to establish apprenticeship programs. These programs are not only beneficial for the industry but also for aspiring professionals looking to build a successful career in plastic injection molding.

The Lanier Tech Quality Control Apprenticeship Program offers students a unique opportunity to gain real-world experience and hands-on training, something indispensable in the plastic injection mold industry. It's a highly technical field where theoretical knowledge alone falls short. This apprenticeship program creates the ideal environment for students to acquire practical skills, such as operating complex machinery and troubleshooting production challenges. Lanier Tech makes certain that apprentices are well-equipped to meet the demands of plastic injection mold manufacturing.

Apprenticeship programs serve as an excellent recruitment tool for us at Murray Plastics. Through our partnership with Lanier Tech, we can identify promising students, nurture their skills, and potentially offer them full-time employment upon program completion. This approach streamlines the hiring process and grants us access to a pipeline of skilled workers who are already familiar with our operations and values.

The collaboration between Murray Plastics and Lanier Tech in this apprenticeship program isn't just a temporary fix for the skills gap. It fosters long-term sustainability by establishing a continuous cycle of skilled workers entering the industry. Over time, this approach will help us build a stable and proficient workforce capable of adapting to technological advancements and evolving industry demands.

Partnerships like this are a game-changer for the industry. It effectively addresses the skills gap, provides students with invaluable hands-on experience, and ensures that the plastic injection mold sector remains competitive and innovative. As the industry continues to evolve, and as we at Murray Plastics evolve with it, these collaborative programs will be instrumental in shaping the future of mold manufacturing, nurturing a skilled workforce, and fostering economic growth. It's a model that underscores the importance of education and industry working hand in hand to secure a brighter future for the plastic injection mold business.

In the world of plastic injection molding, staying ahead of the curve is paramount. With advancements in technology and a growing demand for precision, the need for skilled professionals in the field is more critical than ever. To tackle this challenge, plastic injection mold businesses can form partnerships with technical colleges to establish apprenticeship programs. These programs are not only beneficial for the industry but also for aspiring professionals looking to build a successful career in plastic injection molding.

The Lanier Tech Quality Control Apprenticeship Program offers students a unique opportunity to gain real-world experience and hands-on training, something indispensable in the plastic injection mold industry. It's a highly technical field where theoretical knowledge alone falls short. This apprenticeship program creates the ideal environment for students to acquire practical skills, such as operating complex machinery and troubleshooting production challenges. Lanier Tech makes certain that apprentices are well-equipped to meet the demands of plastic injection mold manufacturing.

Apprenticeship programs serve as an excellent recruitment tool for us at Murray Plastics. Through our partnership with Lanier Tech, we can identify promising students, nurture their skills, and potentially offer them full-time employment upon program completion. This approach streamlines the hiring process and grants us access to a pipeline of skilled workers who are already familiar with our operations and values.

The collaboration between Murray Plastics and Lanier Tech in this apprenticeship program isn't just a temporary fix for the skills gap. It fosters long-term sustainability by establishing a continuous cycle of skilled workers entering the industry. Over time, this approach will help us build a stable and proficient workforce capable of adapting to technological advancements and evolving industry demands.

Partnerships like this are a game-changer for the industry. It effectively addresses the skills gap, provides students with invaluable hands-on experience, and ensures that the plastic injection mold sector remains competitive and innovative. As the industry continues to evolve, and as we at Murray Plastics evolve with it, these collaborative programs will be instrumental in shaping the future of mold manufacturing, nurturing a skilled workforce, and fostering economic growth. It's a model that underscores the importance of education and industry working hand in hand to secure a brighter future for the plastic injection mold business.

Last modified: January 9, 2024

In the world of plastic injection molding, staying ahead of the curve is paramount. With advancements in technology and a growing demand for precision, the need for skilled professionals in the field is more critical than ever. To tackle this challenge, plastic injection mold businesses can form partnerships with technical colleges to establish apprenticeship programs. These programs are not only beneficial for the industry but also for aspiring professionals looking to build a successful career in plastic injection molding.

The Lanier Tech Quality Control Apprenticeship Program offers students a unique opportunity to gain real-world experience and hands-on training, something indispensable in the plastic injection mold industry. It's a highly technical field where theoretical knowledge alone falls short. This apprenticeship program creates the ideal environment for students to acquire practical skills, such as operating complex machinery and troubleshooting production challenges. Lanier Tech makes certain that apprentices are well-equipped to meet the demands of plastic injection mold manufacturing.

Apprenticeship programs serve as an excellent recruitment tool for us at Murray Plastics. Through our partnership with Lanier Tech, we can identify promising students, nurture their skills, and potentially offer them full-time employment upon program completion. This approach streamlines the hiring process and grants us access to a pipeline of skilled workers who are already familiar with our operations and values.

The collaboration between Murray Plastics and Lanier Tech in this apprenticeship program isn't just a temporary fix for the skills gap. It fosters long-term sustainability by establishing a continuous cycle of skilled workers entering the industry. Over time, this approach will help us build a stable and proficient workforce capable of adapting to technological advancements and evolving industry demands.

Partnerships like this are a game-changer for the industry. It effectively addresses the skills gap, provides students with invaluable hands-on experience, and ensures that the plastic injection mold sector remains competitive and innovative. As the industry continues to evolve, and as we at Murray Plastics evolve with it, these collaborative programs will be instrumental in shaping the future of mold manufacturing, nurturing a skilled workforce, and fostering economic growth. It's a model that underscores the importance of education and industry working hand in hand to secure a brighter future for the plastic injection mold business.

In the world of plastic injection molding, staying ahead of the curve is paramount. With advancements in technology and a growing demand for precision, the need for skilled professionals in the field is more critical than ever. To tackle this challenge, plastic injection mold businesses can form partnerships with technical colleges to establish apprenticeship programs. These programs are not only beneficial for the industry but also for aspiring professionals looking to build a successful career in plastic injection molding.

The Lanier Tech Quality Control Apprenticeship Program offers students a unique opportunity to gain real-world experience and hands-on training, something indispensable in the plastic injection mold industry. It's a highly technical field where theoretical knowledge alone falls short. This apprenticeship program creates the ideal environment for students to acquire practical skills, such as operating complex machinery and troubleshooting production challenges. Lanier Tech makes certain that apprentices are well-equipped to meet the demands of plastic injection mold manufacturing.

Apprenticeship programs serve as an excellent recruitment tool for us at Murray Plastics. Through our partnership with Lanier Tech, we can identify promising students, nurture their skills, and potentially offer them full-time employment upon program completion. This approach streamlines the hiring process and grants us access to a pipeline of skilled workers who are already familiar with our operations and values.

The collaboration between Murray Plastics and Lanier Tech in this apprenticeship program isn't just a temporary fix for the skills gap. It fosters long-term sustainability by establishing a continuous cycle of skilled workers entering the industry. Over time, this approach will help us build a stable and proficient workforce capable of adapting to technological advancements and evolving industry demands.

Partnerships like this are a game-changer for the industry. It effectively addresses the skills gap, provides students with invaluable hands-on experience, and ensures that the plastic injection mold sector remains competitive and innovative. As the industry continues to evolve, and as we at Murray Plastics evolve with it, these collaborative programs will be instrumental in shaping the future of mold manufacturing, nurturing a skilled workforce, and fostering economic growth. It's a model that underscores the importance of education and industry working hand in hand to secure a brighter future for the plastic injection mold business.